In partnership with LemnaTec, the global plant phenotyping specialist, scientists at Rothamsted Research have implemented a Field Scanalyzer capable of continuously monitoring the development of crops under field conditions.

The facility will be used initially to understand the development of numerous pre-breeding wheat lines that have been generated through the Wheat Genetic Improvement Network (WGIN) programme supported by Defra and the Wheat Initiative Strategic Programme (WISP), funded by the BBSRC and led by the John Innes Centre in collaboration with Rothamsted Research and other university partners.

Dr Malcolm Hawkesford, Head of Plant Biology and Crop Science at Rothamsted, tells the story so far.

Rothamsted Research, based in Harpenden UK, is one of the oldest agricultural research centres in the world. Over its 172 year history, it has built an enviable international reputation as a centre of excellence for scientific research and innovation in support of agricultural productivity, crop protection and soil science.

In partnership with Lemnatec, the global plant phenotyping specialist, scientists at Rothamsted Research have implemented a Field Scanalyzer capable of continuously monitoring the development of crops under field conditions.

The facility will be used initially to understand the development of numerous pre-breeding wheat lines that have been generated through the Wheat Genetic Improvement Network (WGIN) programme supported by Defra and the Wheat Initiative Strategic Programme (WISP), funded by the BBSRC and led by the John Innes Centre in collaboration with Rothamsted Research and other university partners.

To feed our growing population, statistics suggest we need to increase world food production by around 70% by 2050. Wheat provides one fifth of human calories but since 1980 the rate of increase in wheat yields has plateaued. Rothamsted Research is currently working on a programme to increase the potential of wheat production to 20 tonnes per hectare within 20 years, known as 20:20 Wheat.

Dr Malcolm Hawkesford, Head of Plant Biology and Crop Science at Rothamsted, also heads up the 20:20 Wheat programme. Commenting on the research, he says: “In order to get relevant responses to treatments or experimental conditions, we need to monitor crops in the field, not in greenhouses. For some years now, we’ve been increasing the amount of work we do in this area, particularly increasing the number of varieties of wheat and different genetic stocks we look at. So instead of just a few types, we are now looking at thousands of types, but we also want to look at these types in more detail across the lifetime of the crop in the field.”

Translation from greenhouse to field can be problematic because field conditions are often so different to those in the greenhouse. For this reason, field phenotyping is considered to be a key area of development In the Agro industry.

The issue has always been how to extract the data. Around the world, many different techniques have been trialed including walking with sensors, mounting equipment on bicycles or motorised vehicles and even imaging with unmanned drones. However, none of these methods is able to measure with enough accuracy to provide reliable deep phenotyping data.

“The combination of a lot of plants and a lot of detail makes manual phenotyping slow, inefficient and, to be honest, inadequate” continues Dr Hawkesford. “To speed things up, we can use UAVs (unmanned aerial vehicles) to monitor large areas of crops but they are not able to deliver the level of detail that we really need, hence the need for some sort of ground based system.”

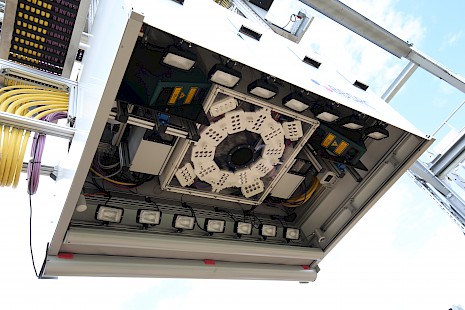

The Field Scanalyzer incorporates a moving gantry that supports a motorised measuring platform carrying multiple sensors. Crops within a 10m x 110m area can be monitored throughout the season with a high degree of resolution and reproducibility. The facility is fully automated and can operate 24 hours per day throughout the year. On board illumination facilitates the data collection and sensors include multi-wavelength imaging systems, an imaging sensor to measure chlorophyll fluorescence decay kinetics and a laser system for 3D visualisation and crop height determination.

The Field Scanalyzer was commissioned in 2014 after Dr Hawkesford saw a prototype system in New Dehli at the Indian Agricultural Research Institute. Following a robust European tender process to evaluate a number of proposed solutions, the Field Scanalyzer from LemnaTec was selected based on criteria including quality, experience, technical know-how and business risk.

“I was looking for a completely automated solution that could operate 24/7 for the whole season. We wanted hyperspectral cameras, 3D information and to look at chlorophyll fluorescence. And that was the basis of the specification for the Field Scanalyzer we purchased from Lemnatec.”

The Scanalyzer is now being used to monitor a selection of six wheat varieties grown at four different nitrogen levels. The process is fully automated, running a series of pre-programmed routines to capture deep phenotyping data about how crops behave in a real-life environment.

“Advances in other technologies have provided a wealth of information about the genetic composition of crop plants. Now, for the first time, we can monitor plants in terms of growth and their physiology throughout their lifetime, in real time under field conditions. This will revolutionise the way that agricultural research is conducted”, Dr Hawkesford concludes.