Seed quality is of highest importance, and germination is the most prominent key factor in seed quality. Frequently, seeds are placed on moist paper to assess germination, and many seed testing guidelines, e.g. ISTA rules, recommend top-of-paper tests for certain seed testing situations.

The testing procedure as such – seed incubation temperatures and duration – is independent of the imaging. The digital image-based assessment presents a new type of tool for the rating procedure. Instead of counting the germinated seeds through an operator who takes notes and feeds data into a computer, the image processing software counts the germination frequency from the images. In this process the germination events are not only counted, but the seedlings are measured in the same time, resulting in parameters such as root- and shoot-length. Thus, the operator gains more information compared to a visual counting, and saves time, because image recording and image processing is less timely compared to counting the germinated seedlings by eye.

With the images and the extended data set, the assessment is reliably documented. This is an advantage compared to the “classical” counting, because there the visual impression is lost after the operator finished the note-taking and eventually discards the sample. In contrast, recorded images can be re-assessed later, e.g. once particularly interesting values occur.

Seeds and their germination are highly diverse. Thus, the image processing software must cope with this variablity. Therefore, our Artificial Intelligence solutions give the possibility to use machine learning.

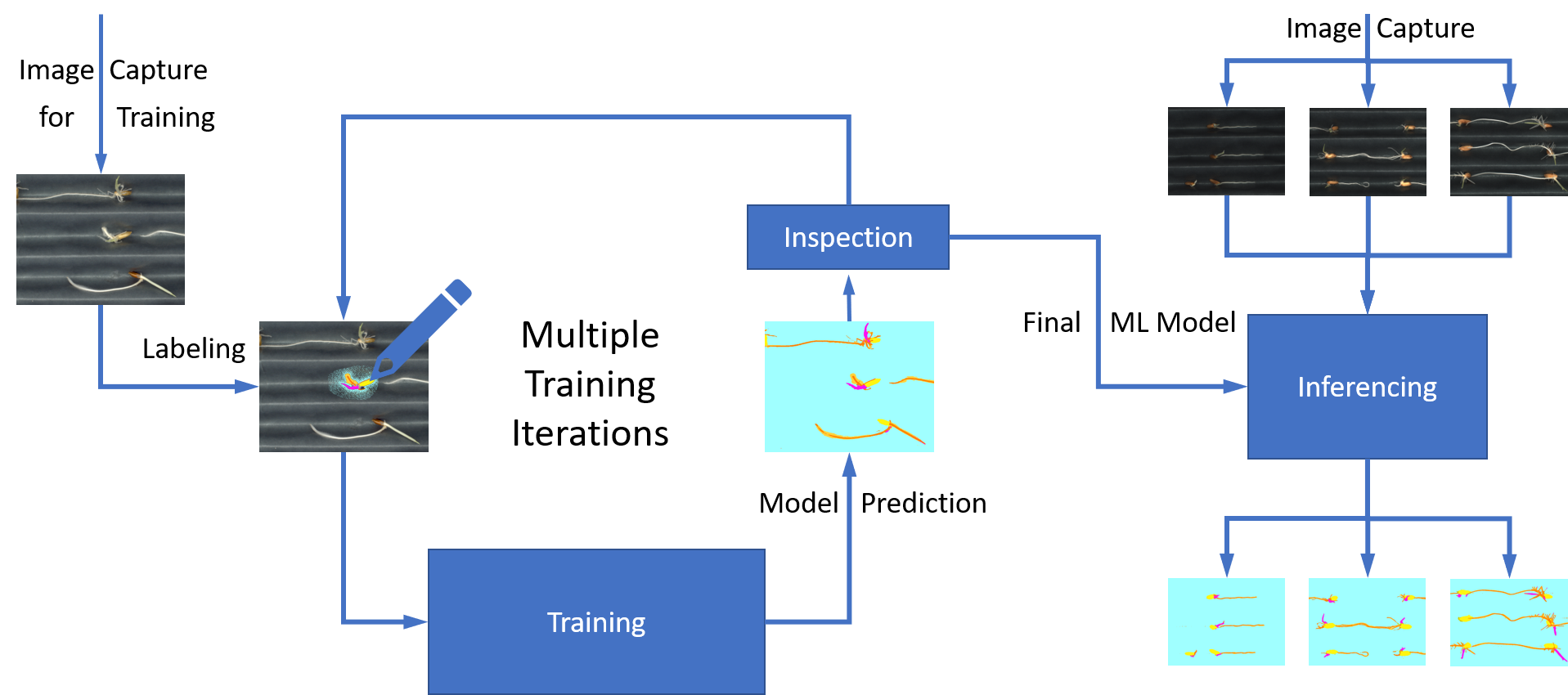

To train the algorithms, we have to present the expert knowledge to the computer system. This works by recording a series of typical images of the sample material. In those images the target structures are labeled by an expert. For common structures, our in-house specialists can do this, but for complex and specific traits we can do it interactively together with the user.

The labeled images go into a training session and the algorithms present a model prediction. This prediction is inspected by a specialist. If it matches the requirements, it’s ready for application. If refinements are required, a new series of labeling and training is started.

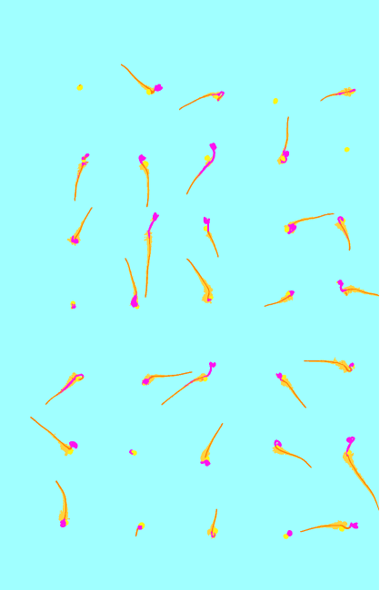

The final models are used for the inferencing process. This is the actual working process where sample images are recorded, and the model automatically recognizes the target structures, counts, and measures them. The resulting numerical values are exported as data sets, e.g. in CSV-format.

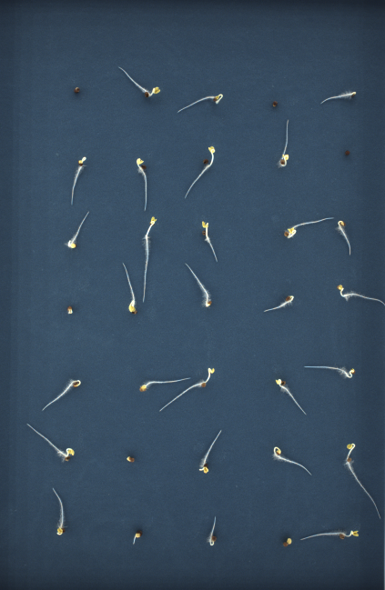

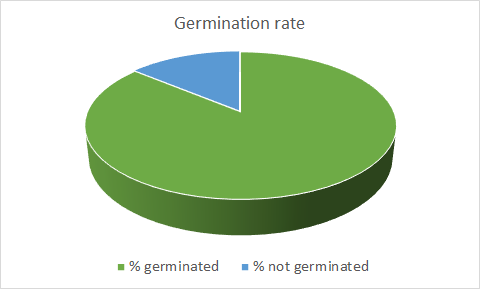

In the current example, cabbage seeds were germinated on moist paper. An image was taken after three days of incubation at 20°C and analyzed with the LemnaTec software. Algorithms were trained to recognize seeds, emerging roots, and shoots.

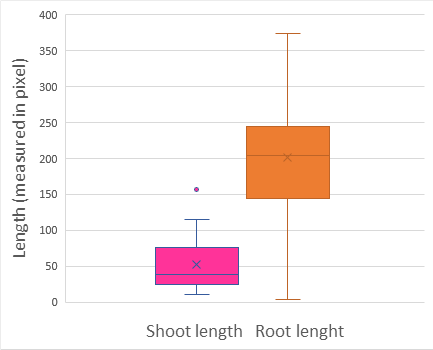

The software detected 86% germination rate. As visible, not all seedlings were equal, particularly root length was different – some just started germinating having quite short roots, while others had already longer roots. Variance in shoot size was lower, with all visible shoots were still short.

The current example gives an insight in the capabilities of our SeedAIxpert product line – the machine learning allows more customized analyses according to testing demands. This includes training the algorithms to recognize seedling quality in terms of germination normality or usable plant determination.